The textile industry is one of the largest contributors to pollution and resource depletion globally. Key environmental challenges include:

1. Water Consumption and Pollution:

• The production of textiles, particularly cotton, consumes vast quantities of water. For instance, producing one kilogram of cotton requires approximately 20,000 litres of water.

• Textile dyeing and finishing processes contribute to water pollution, releasing harmful chemicals into rivers and streams.

• Washing synthetic textiles releases microplastics into water systems, which eventually enter waterways and oceans, harming aquatic life.

2. Carbon Emissions:

• The industry is a significant contributor to greenhouse gas emissions due to energy-intensive manufacturing processes and transportation.

3. Waste Generation:

• Fast fashion trends have exacerbated textile waste, with millions of tons of garments ending up in landfills annually.

4. Microplastics:

• Synthetic fibres such as polyester and nylon shed microplastics during washing, which eventually enter waterways and oceans, harming aquatic life.

Pathways to Sustainability

Transitioning towards a sustainable textile industry is not merely an option—it is a necessity. Here are key strategies:

1. Sustainable Raw Materials:

• Embrace organic and regenerative farming for natural fibres like cotton.

• Utilise recycled fibres and innovative materials such as bamboo, hemp, and bioengineered textiles.

2. Efficient Manufacturing Processes:

• Invest in waterless dyeing technologies and closed-loop systems to minimise waste.

• Transition to renewable energy sources to reduce carbon footprints.

3. Circular Economy Practices:

• Promote recycling and upcycling of garments to extend their lifecycle.

• Implement take-back programmes and design for durability and recyclability.

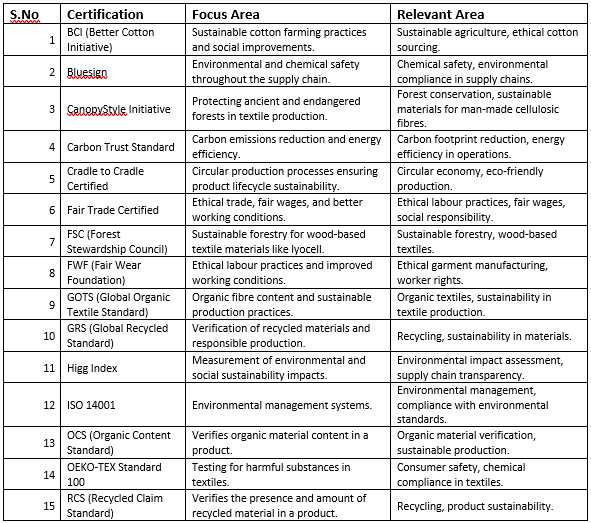

4. Certifications to Maintain Quality and Sustainability:

• Global Organic Textile Standard (GOTS): Ensures organic status and environmentally responsible manufacturing of textiles.

• OEKO-TEX Standard 100: Certifies products free from harmful substances.

• Bluesign Certification: Focuses on reducing environmental impact and ensuring safe chemical use.

• Fair Trade Certification: Promotes ethical labour practices and sustainable production.

• Cradle to Cradle Certified: Recognises safe, circular, and sustainable product design.

• ISO 14001: Provides guidelines for effective environmental management systems.

5. Policy and Regulation:

• Governments and international bodies must enforce stricter environmental regulations and incentivise sustainable practices.

6. Consumer Awareness:

• Educate consumers about the environmental impact of their purchasing choices and encourage them to support sustainable brands.

Table 1: Key Textile and Sustainability Certifications with Focus and Relevant Areas

The Role of Collaboration

Achieving sustainability in the textile industry requires collaboration across the value chain:

• Manufacturers must adopt cleaner technologies and ethical practices.

• Brands and retailers should prioritise transparency and sustainability in their supply chains.

• Consumers have the power to drive change by demanding eco-friendly products.

• Governments and NGOs can provide the necessary framework and support for sustainable initiatives.

Conclusion

The path to sustainability in the textile industry is challenging but attainable. By integrating environmentally conscious practices, fostering innovation, and engaging stakeholders, the industry can transform into a model of sustainability. This transformation is not just about preserving the planet for future generations but also about creating a resilient and equitable industry for all.

20250117163420.png)

20250219104125.png)

Comments